TecnisiaCAD has originated with the word Technology + Asia + CAD. We have a specialization in Automotive, Home appliances and medical industrial engineering sector. Our enriched past experience shows our participation in these industries. Our team is highly experienced, from Industrial background.

Showing posts with label NX Training. Show all posts

Showing posts with label NX Training. Show all posts

Sunday, August 12, 2018

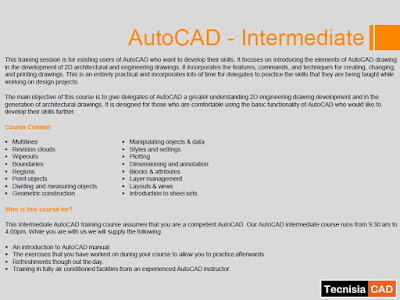

AutoCAD Training Module by TecnisiaCAD

Tuesday, May 29, 2018

Significance of Meshing in Analysis

MESHING IN ANALYSIS

Finite Element Analysis (FEA) provides a reliable numerical

technique for analyzing engineering designs. The process starts with the

creation of a geometric model. Then, the program subdivides the model into

small pieces of simple shapes (elements) connected at common points (nodes).

Finite element analysis programs look at the model as a network of discrete

interconnected elements.

The Finite Element Method (FEM) predicts the behavior of the model

by combining the information obtained from all elements making up the model.

Meshing is a very crucial step in design analysis. The automatic

mesher in the software generates a mesh based on a global element size,

tolerance, and local mesh control specifications. Mesh control lets you specify

different sizes of elements for components, faces, edges, and vertices.

The software estimates a global element size for the model taking

into consideration its volume, surface area, and other geometric details. The

size of the generated mesh (number of nodes and elements) depends on the

geometry and dimensions of the model, element size, mesh tolerance, mesh

control, and contact specifications. In the early stages of design analysis

where approximate results may suffice, you can specify a larger element size

for a faster solution. For a more accurate solution, a smaller element size may

be required.

Meshing generates 3D tetrahedral solid elements, 2D triangular shell

elements, and 1D beam elements. A mesh consists of one type of elements unless

the mixed mesh type is specified. Solid elements are naturally suitable for

bulky models. Shell elements are naturally suitable for modeling thin parts

(sheet metals), and beams and trusses are suitable for modeling structural

members.

Solid Mesh

In meshing a part or an assembly

with solid elements, the software generates one of the following types of

elements based on the active mesh options for the study:

Draft quality mesh

|

The automatic mesher generates

linear tetrahedral solid elements.

|

High quality mesh

|

The automatic mesher generates

parabolic tetrahedral solid elements.

|

Linear elements are also called

first-order, or lower-order elements. Parabolic elements are also called

second-order, or higher-order elements.

A linear tetrahedral element is defined by four

corner nodes connected by six straight edges. A parabolic tetrahedral element

is defined by four corner nodes, six mid-side nodes, and six edges. The

following figures show schematic drawings of linear and parabolic tetrahedral

solid elements.

In general, for the same mesh density (number of elements),

parabolic elements yield better results than linear elements because: 1) they

represent curved boundaries more accurately, and 2) they produce better

mathematical approximations. However, parabolic elements require greater

computational resources than linear elements.

For structural problems, each node in a solid element has three

degrees of freedom that represent the translations in three orthogonal

directions. The software uses the X, Y, and Z directions of the global

Cartesian coordinate system in formulating the problem.

For thermal problems, each node has one degree

of freedom which is the temperature.Shell Mesh

When using shell elements, the software generates one of the

following types of elements depending on the active meshing options for the

study:

| Draft quality mesh | The automatic mesher generates linear triangular shell elements. |

| High quality mesh | The automatic mesher generates parabolic triangular shell elements. |

A linear triangular shell element is defined by three corner nodes

connected by three straight edges. A parabolic triangular element is defined by

three corner nodes, three mid-side nodes, and three parabolic edges. For studies

using sheet metals, the thickness of the shells is automatically extracted from

the geometry of the model.

To set the desired option for a study, right-click the Mesh icon, select Create

Mesh, and expand Advanced.

Shell elements are 2D elements capable of resisting membrane and

bending loads.

| Linear triangular element | Parabolic triangular element |

For structural studies, each node in shell elements has six degrees

of freedom; three translations and three rotations. The translational degrees of

freedom are motions in the global X, Y, and Z directions. The rotational degrees

of freedom are rotations about the global X, Y, and Z axes.

The software generates a shell mesh automatically for the following

geometries:

Sheet metals with uniform thicknesses

|

Sheet metals mesh with shell elements, except for drop test studies.

The software assigns the thickness of shell based on sheet metal thickness. You

can edit the default shell definition before running the study, except

thickness.

|

Surface bodies

|

Surface bodies mesh with shell elements. The software assigns a thin shell formulation to each surface body. You can edit the default shell definition before running the study. For Engineering Tutorials: https://www.youtube.com/TecnisiaCAD http://tecnisiacadtraining.business.site

Information Courtesy: SolidWorks Simulation

|

Labels:

3d modeling,

3d printing,

6 week training,

AutoCAD,

Autocad draftsman,

AutoCAD Mechanical,

AutoCAD Mechanical Training,

AutoCAD Training,

CATIA Training,

NX Training,

SLS,

SolidWorks Training,

TecnisiaCAD

Location:

New Delhi, Delhi, India

Friday, April 6, 2018

Best Professional CATIA Training in Delhi

TecnisiaCAD is registered under Ministry of Micro, Small & Medium Enterprises (MSME). We have a team who are Industrial experts, so we understand industrial requirements in better way. In this regard, we endeave to upgrade professional skills of an engineer or technical people so that they can directly start working as per industrial requirements. Our after training placement is very strong because of our large clientle services. They tell us their requirements about candidates and we give them skilled manpower.

We at TecnisiaCAD are responsible for providing CADCAMCAE technologies that leverages Industrial business processes. We offer 6 weeks summer training in CATIA for students which is a fully job oriented project based training that enables students to work on Live design projects from the industry. We provide AutoCAD certification training in Delhi, for students as well as for working professionals.

We are providing Best CATIA course in delhi that can be a turning point for all the students who has undergone B.tech ME or Civil, Diploma in ME or Civil course and many more. In this age of computers and technology it's nearly impossible to get JOBS with just degrees or diplomas. One must be able to understand and have deep knowledge in at least one of the relevant technologies. For students to develop the skills as required by the industry. TecnisiaCAD provides the best CATIA training in delhi with fully equipped labs and enriched project and exercise workbooks.

Unique Features

- Training on 3D CAD modeling of castings, forgings, plastic, sheet metal and machined components

- Training programs designed in consultation with industry experts and professionals

- Experience on projects

- All faculties are Certified by Dassault Systemes for CATIA

Software Content

- Part Design

- Assembly Design

- Drafting

- Surfacing (Generative Shape Design)

- Generative Sheet Metal

Course Certification

Course is Certified by TecnisiaCAD & MSME

Course Duration

6 week – Monday to Friday 2 hours daily of Classroom Lecture and Lab Practice. On Saturday students can practice in the Lab.

TecnisiaCAD Online CATIA Training

Saturday, March 24, 2018

6 Week Summer Training for SolidWorks

Training from TecnisiaCAD gives you a hands-on experience to optimise the use of tools to create better design. The training is conducted by Certified SOLIDWORKS professionals to improve your productivity and knowledge of SOLIDWORKS products. TecnisiaCAD has Best-in-Class Training Facility in Delhi. We also conduct on-site training at our customers premises.

We have dedicated training centre with the best-in-industry facilities for training in SolidWorks at New Delhi. Our Expert faculty and customized training contents helps to provide training of the top most degree in SolidWoks design and Mold design, from basic level to the most advanced levels, depending on the needs of the customer.

This Summer, we have customised our SolidWorks Training as per 4/6 weeks training for delivering the best of SolidWorks as per Industrial standards.

This Summer, we have customised our SolidWorks Training as per 4/6 weeks training for delivering the best of SolidWorks as per Industrial standards.

Thursday, November 16, 2017

AUTOCAD TRAINING - TECNISIACAD

2D Drafting & 3D Modeling Training using AUTOCAD

Objective of Course

This course teaches the production of 2D working drawings using AutoCAD instead of a

drawing board. We show you how to create new drawings, edit existing drawings and plot

drawings onto paper. It is entirely practical with a hands-on-approach and you will have your

own professional CAD networked computer. You will be given e-books & practical exercise course

notes.

Agenda

Introduction to the course and hardware

-

- Overview of AutoCAD

- Overview of PC, Peripherals, System Settings and Variables.

- Starting a New Drawing - Menus, Toolbars and Dialogue boxes.

- Drawing Commands - Line, Arc, Circle, Polygon, Blocks, Plines, Ellipses, Hatch, Text, Dimensions.

- Edit Commands - Erase, Array, Extend, Break, Trim, Mirror, Copy, Grips, Change, Rotate, Pedit, Etc.

- View Commands - Redraw, Zoom, Pan, Etc. Drawing Settings and Aids - Snapping to points, Grids, Precision input, Coordinates, Line and Text Styles, Drawing Limits, Layers, Units, Template Drawings.

- Assist Commands - Help! Cancel, Undo, Redo. Saving and Plotting Drawings

- Productivity Tools - Blocks, Dynamic Blocks

- Associative Tools - OLE, Hyperlinks

The above may be varied to suit clients preferences and requirements.

At the end of the course the trainee will have produced a number of 2D drawings. These will

be at the correct scale, showing text, dimensions and printed onto paper using varied line

weights.

New users of AutoCAD. Previous computer or CAD use is not required but we would recommend you have some experience on windows. Drawing board skills are very useful. Managers requiring an overview of AutoCAD for evaluation or management purposes.

Qualifications

At the end of the course you will be presented with a TecnisiaCAD AutoCAD Certificate.

TecnisiaCAD Links:

Facebook | Twitter | YouTube | Google Plus | LinkedIn | BlogSpot | Instagram | Sulekha

Official Website: www.tecnisiacad.in

Email: info@tecnisiacad.in | tecnisiacad@gmail.com

WhatsApp/Call: (+91) - 9716764006

Company Profile: https://www.youtube.com/watch?v=oV0naudz96M

Subscribe to:

Posts (Atom)